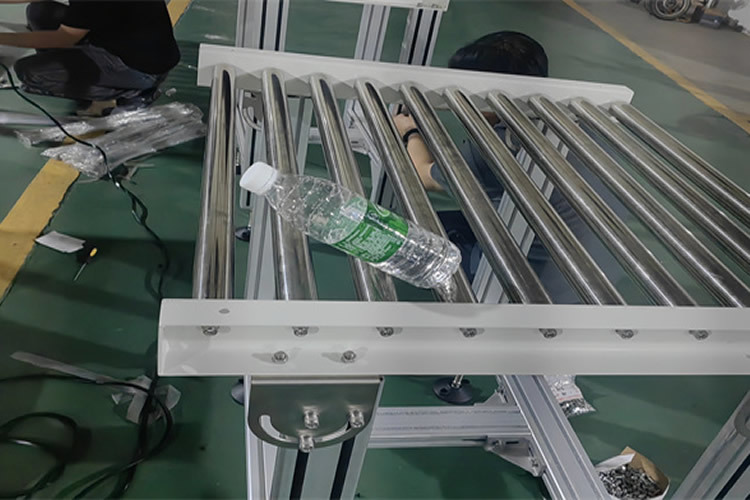

Mine belt conveyor machine structure design and installation of what standard?

Release time:

2024-05-09

In the structural design and installation of mine belt conveyor, it is necessary to follow a series of standards and specifications to ensure its safe and efficient operation, in line with relevant national standards and regulations: the design of mine belt conveyor should strictly abide by the "Mine Belt Conveyor Design Code", "Coal Mine Safety Regulations" and other relevant national standards and regulations.

In the structural design and installation of mine belt conveyor, it is necessary to follow a series of standards and specifications to ensure its safe and efficient operation. Here are some key criteria and points:

I. Structural Design Standards

In line with the relevant national standards and regulations: the design of mining belt conveyor should strictly comply with the "Mine Belt Conveyor Design Code", "Coal Mine Safety Regulations" and other relevant national standards and regulations.

Consider the characteristics of material conveying: according to the characteristics of the material being conveyed (such as adhesion, corrosion, agglomeration, etc.), select the appropriate conveyor belt material, conveyor structure and cleaning device to ensure that the material can be transported smoothly and efficiently.

Determine the appropriate parameters: According to the parameters such as conveying distance, conveying volume and process requirements, reasonably determine the working speed, bandwidth and transmission mode of the conveyor to achieve the best conveying effect.

Pay attention to safety protection: fully consider safety protection measures in the design, such as emergency shutdown device, anti-deviation device, slip detection device, etc., to ensure that the equipment can stop quickly under abnormal conditions and reduce accident losses.

2. installation standard

Equipment inspection: Before installation, conduct a comprehensive inspection of the equipment to ensure that the equipment is intact, all components are complete, and there is no damage or missing.

Installation site preparation: the installation site should be flat, dry, no water and debris to ensure the safety and smooth progress of the installation process.

Installation personnel training: installation personnel should be professionally trained, familiar with the equipment installation requirements and operation process, with relevant safety protection knowledge and skills.

Installation sequence: install according to the equipment installation sequence, first install the support frame, then install the conveyor body, and finally install the conveyor belt and transmission device.

Installation accuracy: During the installation process, it is necessary to ensure the levelness and verticality of the equipment, as well as the clearance and matching accuracy of each component to ensure the normal operation of the equipment after installation.

Fixed connection: the connection of each component should be fixed by special bolts and nuts, and the fastening force of the fasteners should meet the requirements to ensure that the equipment will not loosen or fall off during operation.

Safety protection: during the installation process, it is necessary to strictly abide by the relevant safety operation procedures and wear safety protection equipment to ensure the personal safety of the installation personnel. At the same time, set up obvious safety warning signs around the equipment to remind personnel to pay attention to safety.

In short, the structural design and installation of mine belt conveyor should be carried out in strict accordance with relevant standards and specifications to ensure the safe and reliable operation of the equipment.